Why Choose the Right Raised Access Floor Manufacturer Matters

Let’s start with the basic point: raised access floors aren’t just “fancy floors.” They’re the unknown heroes of modern buildings—using metal pedestals and stringers to lift panels 3cm to 150cm off the ground, creating a hidden space for cables, cooling tubes, and wires . In 2025, with AI and cloud computer booming, data centers alone add over 1MW of new load

daily in the U.S.—and every one of those servers sits on these floors .

Think of them like a building’s circulatory system. If the system fails, everything stops. A shoddy manufacturer might cut corners on materials, leading to floors that crack under server weight or fail fire safety checks. Suddenly, you are facing high downtime costs, equipment reinstallation, and even violation fines. Why take the risk? Making the right choice from the beginning is the only way to avoid future troubles (and costs).

The Hidden Backbone of Modern Spaces

From Silicon Valley data centers to Wall Street trading floors, these floors do two duties: they support tons of equipments and keep hidden infrastructure organized . A good manufacturer designs floors that increase energy efficiency and short maintenance. A bad one? You’ll be crawling under the panel every month fixing loose panels or tangled wires.

The Cost of Choosing Poor

Imagine this: You install cheap floors in your data center. Six months later, a panel collapses under a server rack. Not only do you need to replace the server (thousands of dollars), but also you lose days of business while fixing the floor. Or worse—non-compliant fire ratings make your building shut down during an inspection. The little savings aren’t worth the disaster.

First Step: Define Your Exact Needs (Don’t Skip This!)

Before you even Google “manufacturers,” you need to know what you’re looking for. It’s like buying shoes: you wouldn’t grab size 10s if you wear a 7, right? Your needs decide everything from material to price.

Identify Your Use Case

Every space has unique demands. Let’s break down the big ones:

Data Centers vs. Office Spaces

Data centers need panels that handle heavy loads (we’re talking 2000+ pounds per panel) and conduct static (to protect servers) . Offices? You might prioritize flexibility for rearranging desks and low noise. A manufacturer great for offices might cannot meet data center needs—so be specific.

Specialized Needs (Anti-Static, Fire Resistance)

Do you work with sensitive electronics? Anti-static floors (with resistance between 10⁶-10⁹Ω) are non-negotiable . Healthcare facilities need waterproof, easy-to-sanitize options. Industrial spaces? Fire resistance (meeting GB/T36340-2018 standards) is a must . Remember these “must-haves” before reaching out.

Set Clear Performance Requirements

Don’t just say “strong floors.” Ask: What’s the maximum loading capacity each panel needs to bear? How high do I need the floor raised system? Will it need to handle spills or extreme temperatures? The more details you have, the easier it is to screen manufacturers who can’t deliver.

![Dawn raised floor]()

Evaluate Product Quality: The Non-Negotiable Factor

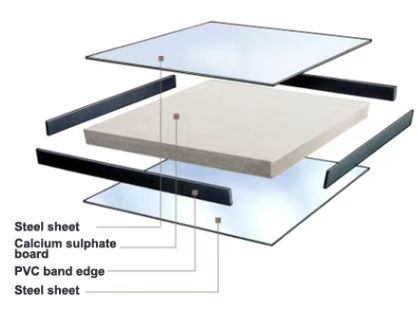

Quality is everything here. A panel’s lifespan depends on what’s inside it and how it’s made. Here’s how to identify the good product:

Check Raw Materials and Production Processes

High-quality floors start with top-class materials—like solid threaded rod or natural (no toxic additives) . Ask manufacturers: “What materials do you use?” and “How do you test them?” Avoid companies that vague answers like “standard materials.”

Looking for automated production lines with mechanical arms—they ensure consistency better than manual work . Some manufacturers even allow you visit their factories (or take online tours) to see the process. Make sure to grasp the opportunity!

Verify Compliance with 2025 Standards

Standards exist for a reason—they keep you safe. In 2025, two big ones matter:

GB/T 36340-2018 and ICC-ES AC175

GB/T 36340-2018 is China’s gold standard for anti-static floors , while ICC-ES AC175 (U.S.) covers structural performance and fire resistance . If your project is in the EEA, CE marking (meeting EN 12825) is required . A reputable manufacturer will voluntarily list these certifications.

PSA Load Grade Specifications

The Access Flooring Association (AFA) uses PSA standards to rate floor strength . For example, a “2000# concentrated load” rating means the floor can handle heavy equipment. Match the grade to your needs—office floors might need 1250#, while data centers need 3000# . Using the wrong grade is a disaster waiting to happen.

Ask for Tangible Proof: Test Reports

Anyone can say their floors are good—make them prove it. Request test reports from independent labs (like the Information Industry Anti-Static Product Quality Supervision and Inspection Center) . Look for results on load-bearing, fire resistance, and static control. If they hesitate? Run.

![Dawn raised floor (2)]()

Assess Manufacturer Credentials and Reputation

A pretty website doesn’t make a good manufacturer. Dig deeper to check their credibility.

Validate Certifications (ISO 9001, ISO 14001, CE)

Certifications are shortcuts to trust—but only if they’re real. Look for ISO 9001 (quality management) and ISO 14001 (environmental standards) . To spot fakes:

How to Spot Fake Certificates

Use the China National Accreditation Service for Conformity Assessment (CNAS) or U.S. National Accreditation Board (ANAB) websites to verify . For ISO certificates, enter the company name or certificate number on the official portal. If it says “suspended” or “revoked,” walk away.

Dive Into Client Reviews and Case Studies

Reviews tell the real story. Check platforms like Google My Business or industry forums for feedback. Look for comments on “installation speed” or “after-sales support”—not just “good product.” Case studies are even better: Changzhou Dawn Building Materials Co.,Ltd shares how they replaced 2000㎡ of floor in 2 days for a bank . That’s the kind of proof you want.

Production Capacity and Customization: Can They Deliver?

You found a manufacturer with great quality—but can they meet your timeline and needs?

Visit the Facility (or Ask for Online Visiting Tours)

A large production base with advanced equipment means they can take big orders . If you can’t visit on site, ask for a video tour. Look for organized warehouses (no piles of untested panels!) and busy assembly lines. A empty factory is a red flag.

Test Their Customization Flexibility

Every project is unique. You might require custom-sized panels for a heritage building or a brand-specific color scheme for your corporate space. Try asking: “Can you modify the floor height or materials to match my project’s needs?” Leading providers, such as Pro Access Floors, tailor solutions for diverse settings—from casinos to classrooms . If a company only offers standardized products, they may not meet your requirements.

Service Quality: From Quote to Post-Installation

Great products mean nothing without great service. A manufacturer should support you every step of the way.

Pre-Sale Consultation: Do They Listen?

A good sales team asks you questions: “What’s your budget?” “What problems are you trying to solve?” A bad one just pushes their most expensive product. If they don’t understand your needs, they can’t deliver a good solution.

Installation Expertise

Installation makes or breaks the floor. Ask: “Do you use your own team or subcontractors?” In-house installers (with 10+ years of experience) are better—they know the product inside out . Subcontractors might cut corners to save time.

After-Sales Support and Warranty

Warranties show confidence. Look for at least 2 years of free warranty (Changzhou Dawn Building Materials Co.,Ltd offers 10 years warranty + lifetime support). Ask: “How fast do you respond to maintenance calls?” and “What does the warranty cover?” (Panels? Installation? Labor?)

Final Step: Compare and Make Your Decision

You’ve done your research—now narrow it down.

Create a Comparison Matrix

List 3-5 top manufacturers and score them on:

This helps you see who excels where. Maybe one is cheaper but has worse service—ask yourself: “Can I afford to fix issues later?”

Trust Your Instincts—But Verify with Facts

Even if a manufacturer meets all the formal requirements, pay attention to subtle red flags—like delayed responses or evasive answers. A successful partnership is built on genuine trust. However, don't let intuition completely dismiss evidence: if their credentials and customer feedback are solid, it may still be worth considering them.

![Dawn raised floor (1)]()

2025 Top Manufacturer Red Flags to Avoid

To wrap up, here’s what to run from:

No test reports or certifications

Vague answers about materials or processes

Poor reviews (especially about installation or warranty)

No case studies for your industry

Unrealistic timelines (“We can install 1000㎡ in a day!”)

In 2025, the raised access floor market is crowded—but the best manufacturers stand out. By clarifying your requirements, verifying quality, and validating credentials, you can secure a partner committed to ensuring lasting safety and functionality in your space.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

Shqip

বাংলা

Hrvatski

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Euskara

Български

Català

ქართული

Hausa

Lietuvių

isiZulu