Introduction

Anti-static raised floors are a crucial component in industries where electronics, sensitive equipment, and clean environments are a concern. These floors are specifically designed to minimize the risk of static electricity, which can cause significant damage to sensitive components and equipment. But how exactly are these floors produced, and what makes them so effective? Let’s dive into the world of anti-static raised floors and understand their manufacturing process, materials, and benefits.

What Are Anti-static Raised Floors?

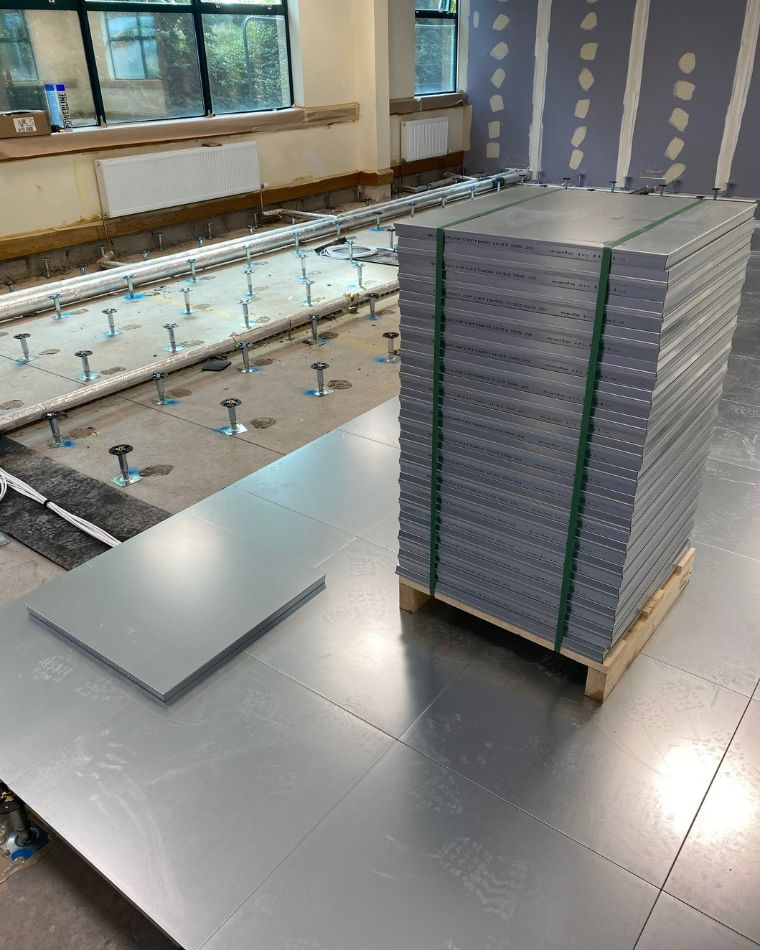

Anti-static raised flooring systems are elevated above the concrete slab to create an air gap for routing electrical cables, ventilation systems and piping. These floors are equipped with special coatings or materials that prevent static electricity buildup, which could harm sensitive machinery, electronics, or even workers.

Why Do Factories Need Anti-static Floors?

Static electricity can be a serious problem in industries like electronics manufacturing, data centers, and clean rooms. Even a small spark of static can destroy delicate circuits or cause fires. Anti-static raised floors offer a solution by controlling static charges and directing them safely to the ground, thus protecting both the equipment and people.The Role of Static in FactoriesStatic electricity occurs when there is an imbalance between positive and negative charges. In factories, This imbalance can build up on surfaces and equipment, creating potential hazards. Exposure to static can cause equipment to malfunction or become damaged, and in extreme cases, catch fire. Anti-static raised floors mitigate these risks.Types of Static Damage

Equipment Failure: Sensitive circuits can short-circuit from static discharges, leading to costly repairs or replacements.

Fire Hazards: Static sparks can ignite flammable materials, causing dangerous fires in factories or clean rooms.

Data Loss: In environments like data centers, static discharges can corrupt valuable data, affecting business operations.

![Raised-access-flooring-installation]()

Materials Used in Anti-static Raised Floors

Anti-static raised floors are made from a variety of materials that provide durability, conductivity, and non-conductive properties. The key is to select materials that not only resist the buildup of static charges but also ensure the structural integrity of the floor system.

Steel Panels

Steel is one of the most commonly used materials in raised floor systems. Its strength and conductivity allow static charges to dissipate safely into the ground. Steel panels are highly durable, which is important in environments where heavy machinery and equipment are used.

Aluminum Panels

Aluminum is another popular choice for raised floors. It is lightweight, resistant to corrosion, and provides excellent conductivity, making it ideal for environments where both static control and ease of installation are needed.

Vinyl and Rubber Coatings

Non-conductive layers are often applied to the surface of the panels in the form of vinyl and rubber coatings. These materials prevent static charge buildup by acting as insulators., while still providing the necessary protection for sensitive equipment.

The Manufacturing Process

Now, let's explore how these anti-static raised floors are actually produced. The manufacturing process involves several key steps, from design and material selection to the final testing.

Step 1: Design and Engineering

The design of anti-static raised floors starts with precise engineering to ensure they meet the specific needs of the industry. Engineers must consider factors like load-bearing capacity, static dissipation, and ease of installation. This step is crucial because a poorly designed floor can lead to inefficiency or even safety issues.

Step 2: Material Selection

Choosing the right materials is the next critical step. Depending on the factory’s needs, the manufacturer will select materials that provide the necessary level of conductivity and durability. For example, In a data centre, a high-conductivity material such as steel may be used, whereas in a clean room, a non-conductive material such as vinyl might be preferred.

Step 3: Panel Construction

Once the materials are selected, the next step is to assemble the panels. The panels are cut to size, and if needed, reinforced with additional layers for extra strength. The frame is built around the panel, and each panel is designed to interlock with others to form a solid floor system.

Step 4: Anti-static Coating Application

After the panels are constructed, a specialized anti-static coating is applied. This coating is often a combination of conductive materials and resins that help dissipate any accumulated static electricity. The coating must be uniform and consistent to ensure its effectiveness across the entire floor system.

Step 5: Testing and Quality Control

Once the anti-static floors are assembled, they undergo rigorous testing to ensure they meet industry standards. Testing includes checking the conductivity, strength, and durability of the floors. Manufacturers often use advanced equipment to simulate real-world conditions and ensure the floors perform as expected.

Advantages of Anti-static Raised Floors

Anti-static raised floors offer numerous advantages to industries where static control is critical. Let’s take a look at some of the key benefits these floors provide.

Enhanced Safety

One of the most significant benefits of anti-static raised floors is enhanced safety. By preventing static discharge, these floors help reduce the risk of equipment damage, fires, and workplace accidents. This is especially important in industries like electronics and pharmaceuticals.

Increased Efficiency

Anti-static floors also contribute to increased efficiency. Since they allow for better airflow and cable management, factories can optimize their workspace. This makes it easier to maintain equipment, reduce clutter, and streamline operations.

Cost-Effectiveness

While the initial installation of anti-static raised floors can be expensive, they can save factories a considerable amount of money in the long run. By preventing equipment failure, reducing maintenance costs, and improving operational efficiency, these floors are a smart investment.

Applications of Anti-static Raised Floors

Anti-static raised floors are used in a variety of industries. Here are some of the most common applications:

Electronics Manufacturing

In electronics manufacturing, preventing static discharge is critical. Anti-static raised floors provide a safe environment for assembling sensitive equipment like microchips, circuit boards, and other electronic components.

Data Centers

Data centers house servers and other critical systems that are highly sensitive to static electricity. Anti-static raised floors help maintain a stable environment, preventing costly disruptions or damage to data storage equipment.

Clean Rooms

Clean rooms are controlled environments where the level of contamination must be kept to an absolute minimum. Anti-static flooring helps to prevent the build-up of particles and dust that could compromise air quality and product safety.

![Perforated-Raised-Floor-Panel-Tiles- Perforated-Raised-Floor-Panel-Tiles-]()

Conclusion

Anti-static raised floors play a vital role in protecting sensitive equipment and ensuring safety in factories, data centers, and clean rooms. Their unique design and manufacturing process, which focuses on durability, conductivity, and safety, make them an indispensable component in many industries. Whether you’re dealing with electronics, data storage, or pharmaceutical manufacturing, these floors provide the perfect solution for controlling static and ensuring smooth operations.

Dawn floor follow a strict and efficient production process, ensuring high-quality standards at every stage. From design to final product delivery, we utilize advanced technology and continuous quality control to guarantee precision and consistency. Our commitment to excellence allows us to meet and exceed customer expectations with every order.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

Shqip

বাংলা

Hrvatski

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Euskara

Български

Català

ქართული

Hausa

Lietuvių

isiZulu